NEURO-Train, 3D printed simulators for cranial access training

The NEURO-Train range, simulators co-developed with neurosurgeons

NEURO-Train surgical simulators are educational tools for training professionals specifically in cranial access training. They enable training in a variety of procedures that can be performed in this field.

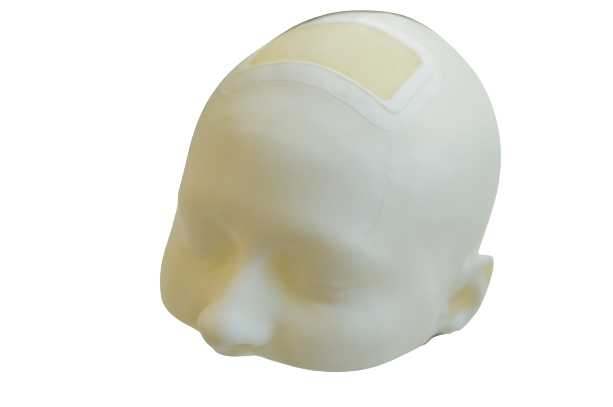

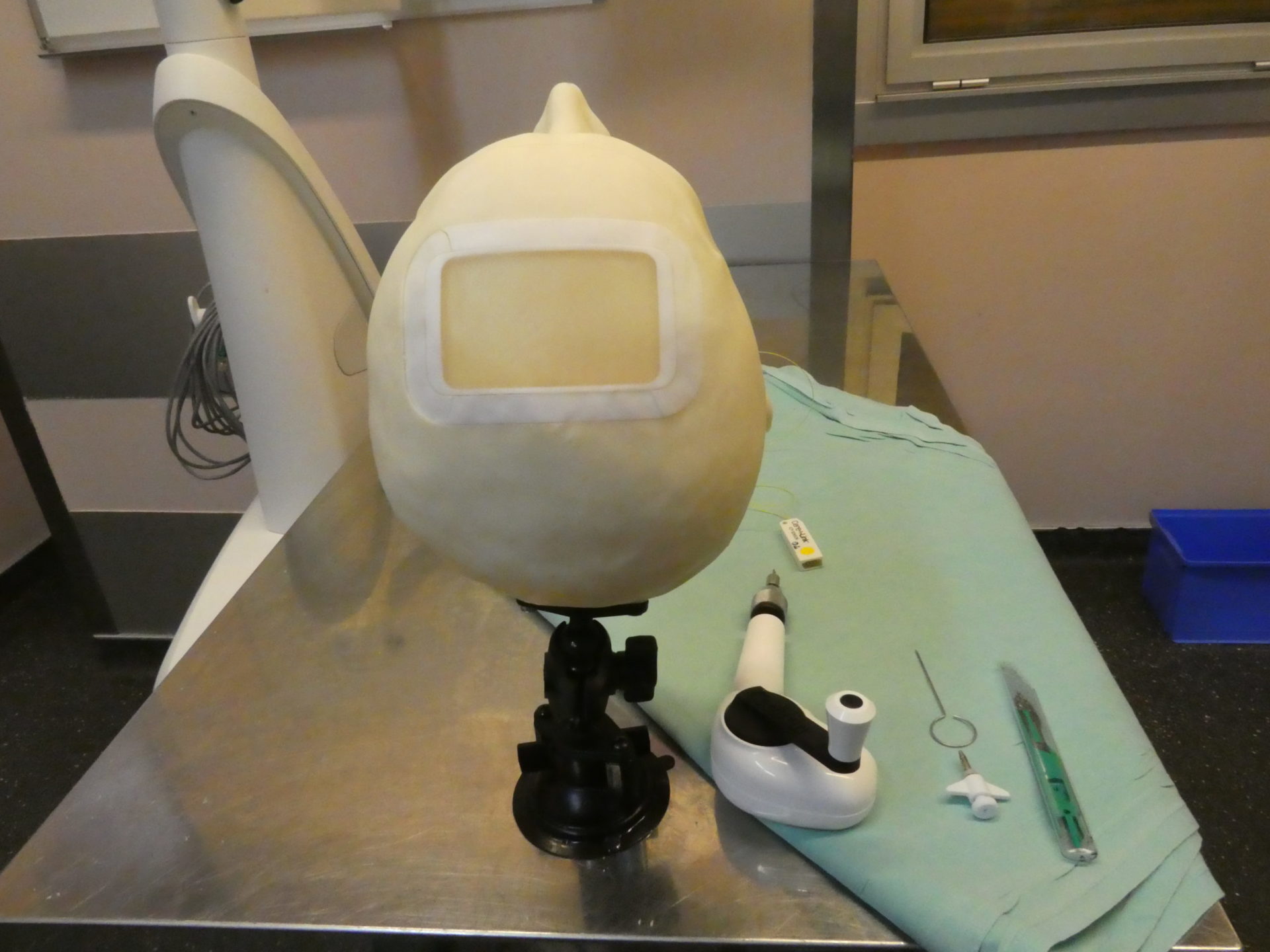

NEURO-Train consists of a cartridge that fits into a reusable simulation environment. You have the option of choosing between:

- 2 environments to choose from: Harvey (large ventricles) and Augusta (small ventricles)

- 2 cartridges to choose from: with or without a brain

The cartridges are composed of the following elements, validated by our experts:

- Skin

- Bone Cortical

- Bone Spongious

- Dura-mater

- Brain (for the cartridge “with brain”)

Modular models for various intracranial surgical procedures

The NEURO-Train simulators will allow you to perform many procedures essential to the training of neurosurgeons and other specialties wanting to train in cranial access.

You will be able to perform skin incisions, bone drilling, dura drilling…

Available standard models and associated feasible acts:

Use of the brainless model

Use of the with brain model

Technical specifics of 3D surgery simulators

a range of Realistic simulators that are adjustable according to the needs of the user

Create customizable models that can be scaled from your patient data.

“Patient-specific” templates

Practice on multi-subject simulators.

For accurate and realistic features .

Design multi-purpose simulators.

Repeat an act on a single cartridge.

Position your simulator on an articulated arm.

For better ergonomics.

Couple your simulator with a neuronavigation system

To complete your training.

Discover our range of surgical simulators for different specialties.

Photo, video, & article resources

Downloadable documents

Frequently asked questions

Most of our surgical simulators are composed of two elements:

- A reusable simulation environment reproducing the anatomical region of interest, allowing a close-to-reality product

- A single-use cartridge, which allows you to keep your simulation environments for a long time, changing only what is necessary

Our team of engineers systematically performs a feasibility study beforehand to evaluate each project: we have the ability to tell you if 3D printing is the best solution (compared to machining or other).

We are totally transparent about our ability to meet your expectations.

In the context of simulators, the design is based on patient medical imaging and also on surgical sensations (qualitative and quantitative evaluation).

The design is based on the analysis of the act that will be performed on the model: each act is validated by an expert (a mandible dedicated to implantology for example will not have the same material as a model dedicated to bone grafting).

Today we do not have the capacity to recycle our own parts, it is companies specialized in this field that do it.

However, 3D printing allows an optimal use of the material: there is no waste (compared to machining), no loss of stock and the production of your parts is done nearby.