The French medtech that brings the best of 3D printing to the medical world.

Since 2018, our mission is to develop the use of additive printing in the medical world.

Advances in 3D printing technologies allow us to provide hospitals with high-quality personalised medicine at a lower cost, for the comfort and safety of doctors and patients. They are also revolutionising the training of surgeons, medical and paramedical specialists, and nursing staff by realistically reproducing healthy or pathological anatomical environments.

Standard or customised medical devices, procedure simulators and anatomical models, all our products are codeveloped by our bioengineers and medical experts in their field.

Our HospiFactory solution provides healthcare facilities with an integrated offer that includes a 3D printing platform tailored to their structure and a dedicated team of experts to design and print their products locally.

Governance

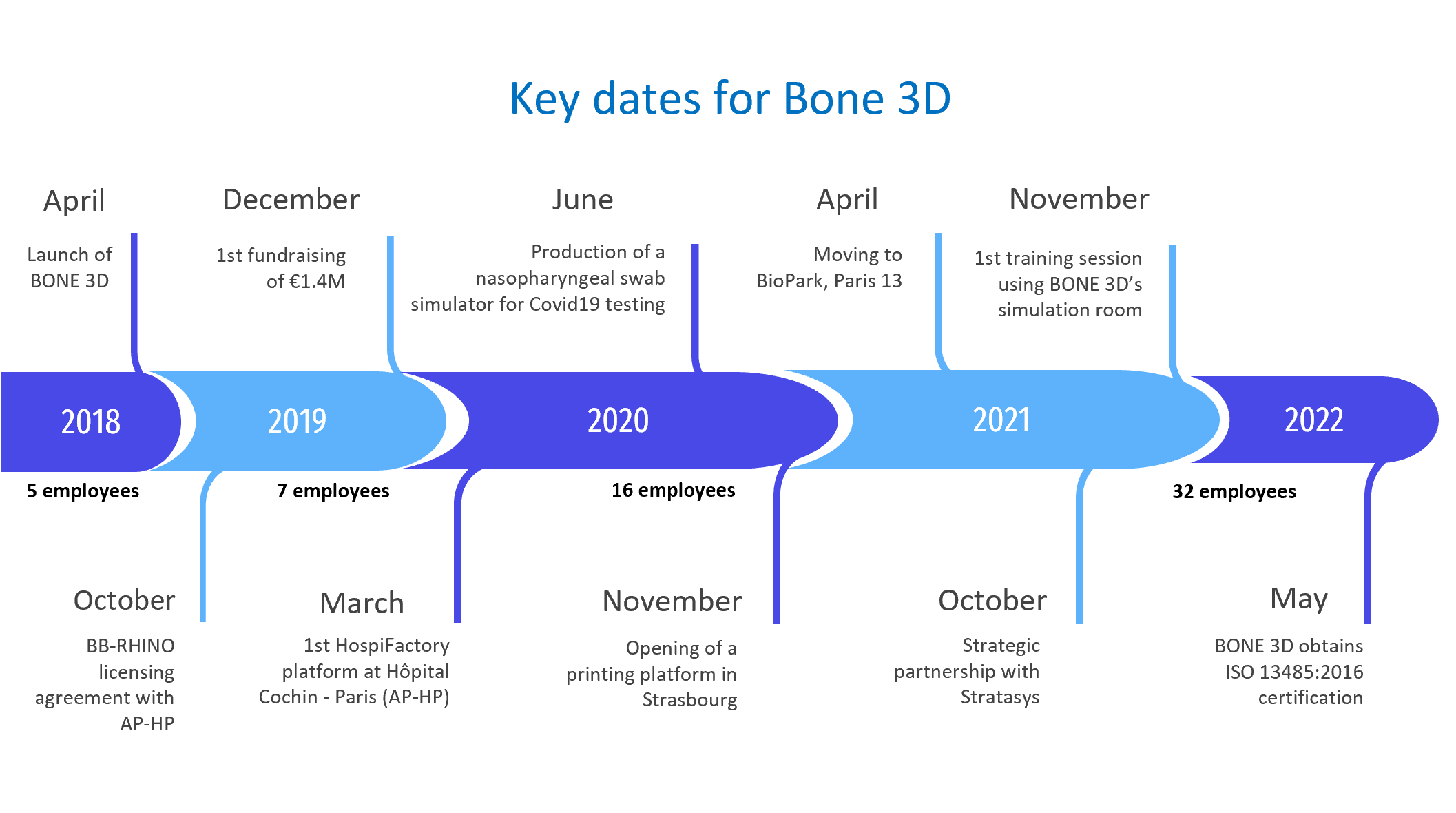

BONE 3D is a SAS created in April 2018. The shareholders form the Board of Shareholders, which appoints a Strategic Committee from among its members.

The implementation of the Strategic Plan and the operational follow-up are carried out by the Management Committee, composed of the managers of the different departments of BONE 3D and chaired by Jérémy Adam, President and founder of BONE 3D.

Board of Shareholders

The members whose names are in italics make up the Strategic Committee, chaired by Padam

Individual members

Jérémy Adam, CEO and Founder

Dr Serge Ketoff, maxillo-facial surgeon and stomatologist, Hôpital Saint Joseph

Dr Ludovic Bénichou, maxillo-facial surgeon and stomatologist, Clinique du Louvre

Dr Stephan Gaillard, neurosurgeon, Hôpital de la Pitié-Salpétrière

Daniel Messler, pharmacist

Members legal entities

Padam SAS

Arbois Finance Invest (AFI)

SC I&CW

Cap Bone

BD Holding

Management Committee

Jérémy Adam, CEO

Camille Bonnassieux, Regulatory Affairs and Quality Manager

Sandrine Chevallier, Head of Human Resources

Sylvie Delassus, Head of Communication and Marketing

Pierre-Marc François, Chief Technical Officier

Jonas Kosior, Production Manager

Antoine Szczypa, Business Manager

Our beliefs

At BONE 3D, everyone has a place and a role to play. Our customers and suppliers are important partners to whom we listen.

We believe in the richness of diversity and are always curious to share new approaches, cultures, or customs.

We treat all our partners and suppliers as we would like to be treated ourselves!

Our mission is meaningful. We are committed to putting our technical skills and ideas at the service of our customers, partners and colleagues.

Our expertise

Cutting-edge technologies

Our platforms are composed of the latest generation 3D printers offering a wide range of technologies to meet your needs in the best possible way.

Interesting models to reproduce the bone level in a realistic way. This allowed the students to practice. These simulators really reproduce the reality of the patient.

Dr Davido

Dental SurgeonOur expertise

A team of experts

Our research and development team is composed of engineers and doctors in biomechanics who are experts in 3D health modeling. They are trained to the specificity of our printers and can thus get the best out of them. Our production team is continuously trained on the new developments proposed by the printer manufacturers and our partnerships with them guarantee you access to the best technologies.

Wow effect: Bone 3D brings a real expertise! The team is composed of real experts, efficient, flexible and adaptable to any situation. Availability and benevolence guaranteed!

M. de Bazelaire

Director, Imagine InstituteOur expertise

Customised designs

Our products are co-designed with doctors and surgeons to perfectly meet the needs of practitioners. They can also be customized according to patient data or industrial constraints.

Bone 3D has contributed to the improvement of our service by allowing us to develop customized material for our patients. A real time saver on a daily basis!

F. Chagny

Occupational TherapistOur expertise

Demanding quality criteria

Our regulatory team ensures compliance with applicable standards and the quality of our products and processes. Bone 3D obtained ISO 13485 certification in May 2022.

All our teams are regularly trained to respect the quality procedures applicable to medical devices.

J. Adam

President, Bone 3D