Medical 3D printing expertise that meets your hospital's needs

How does HospiFactory help you?

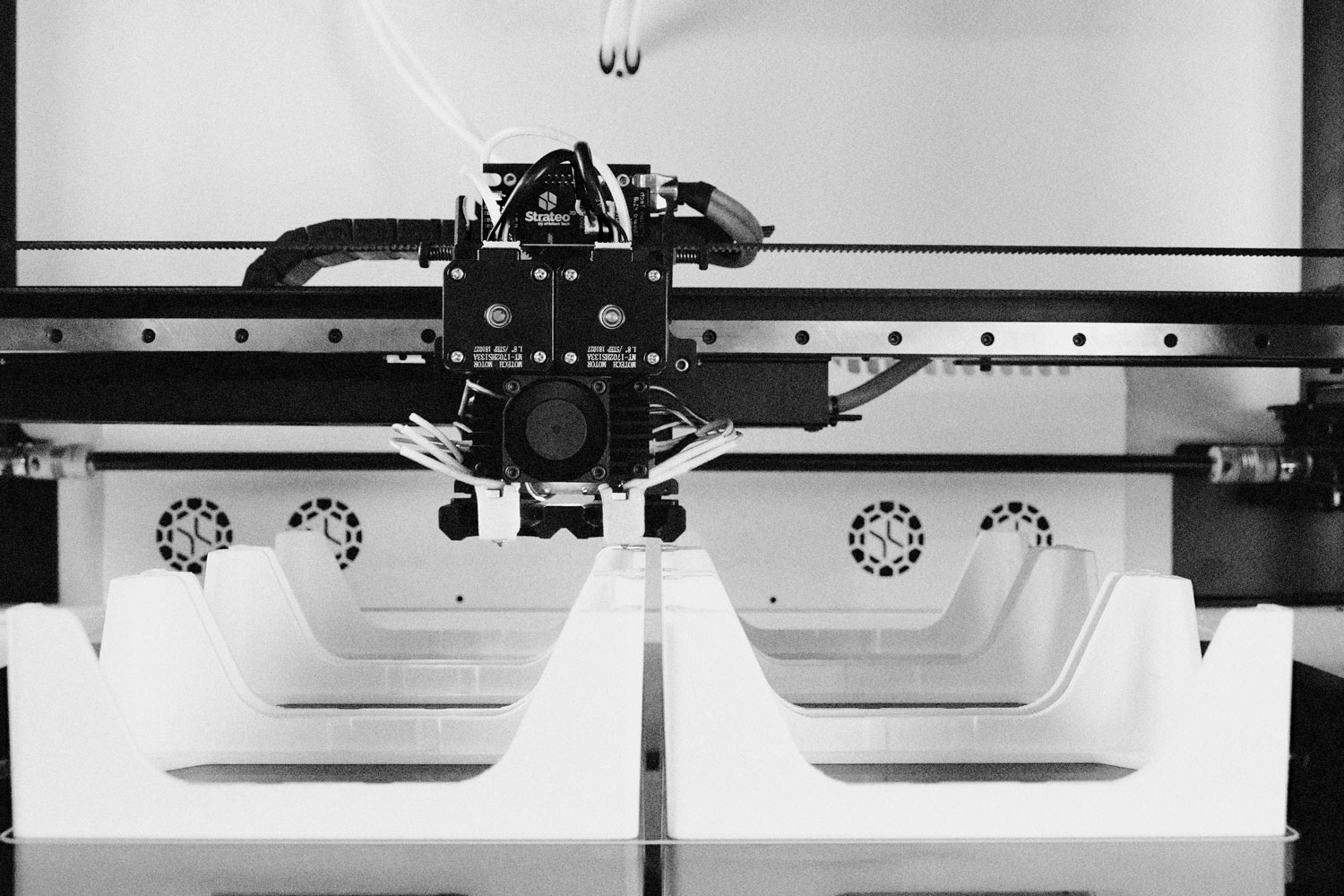

HospiFactory is an opportunity for your facility to innovate its practices by 3D printing products to anticipate interventions, increase patient education or create new care devices.

In addition to providing new care solutions, HospiFactory serves your hospital. It helps maintain the quality of the equipment, as well as ensuring your safety and comfort.

Beyond 3D printers, Bone 3D provides its team of experienced biomedical engineers to support the entire system

Thanks to HospiFactory, 3D print the parts you need, as you imagined them!

Together, we define the service most adapted to your structure and budget.

- – Evaluation of your needs in materials and 3D technologies

- – Provision of a dedicated or shared platform

- – Training your teams on the HospiFactory process and marketplace

We collect your requests online.

- – Requests from caregivers and hospital services to a defined referent

- – Printing requests to Bone 3D by the hospital's referent

- – Processing of incoming requests by Bone 3D

We develop your idea together.

- – Medical imaging segmentation by the engineering office

- – Technologies selected according to your objectives

- – Prototyping iteration

We bring your project to life.

- – Manufacturing and post-processing of the requested products

- – Shipment and validation of products

- – Regulatory support for your innovative projects

No commitment, form filled in only 2 minutes.

OUR expertise & engagement

HospiFactory it’s also

5 different 3D printing technologies (SLA, FDM, Polyjet, SLS, SLM) and up to 50 materials available to make the parts you need.

A catalog of more than 200 predefined or customized parts, for the benefit of the entire hospital: care services, maintenance, biomedical engineering.

A monthly subscription tailored to your structure.

Who is HospiFactory for?

HospiFactory meets all the needs of your healthcare staff and patients.

For your organization

Enable your hospital facility to innovate every day and bring new 100% custom devices to life with 3D printing.

Unlike traditional manufacturing, the complexity of a part is an almost non-existent constraint in 3D printing, allowing you to bring your ideas to life with great freedom.

With real-time unique part creation, your hospital will position itself as leader in the creation of new technologies.

With 3D printing, fulfill your innovation potential.

For department heads/healthcare executives

“A 3D-printed wall hanging system for blood samples avoids the need for large carts that take up space.” Edouard, healthcare executive

“Faulty equipment on the wards wastes teams’ time in delivering care.” Audrey, ICU nurse

Replace your equipment quickly, so you can work in good conditions and your patients receive the best possible care.

With 3D printing, optimize your staff’s days and boost their efficiency.

For your medical staff

“Never the first time on a patient.”

Provide your medical teams with innovative 3D-printed procedural simulators and educational tools to allow them to practice performing a procedure, an essential step in training or planning a complex surgical operation.

With 3D printing, improve the working conditions of your caregivers and increase surgical ‘experince’.

For your paramedical staff

“As an occupational therapist, we often need to create custom pieces for our patients’ rehabilitation sessions.” Franck, occupational therapist

Often they have to tinker with it themselves by hand or order it (and again if she can find them on the market) but it wastes a lot of her time. They would love to be able to imagine and create suitable materials quickly!

Bone 3D also helps you with the design of innovative medical devices.

With 3D printing, design your own care equipment and develop your independence.

For your non-medical staff

Your maintenance department can sometimes be inconvenienced by the unavailability of spare parts, and this can slow them down in their missions, and adds a lot of complexity to their work.

If they could print a single part instead of ordering 250 or having to make a capital request for a total equipment replacement, they could more quickly to the requests of different departments

With 3D printing, help your facility improve every day.

For your patients

Incourage patient involvement in their care journey and allow them to be an actor in their care by educating them on anatomical models that are close to real life.

Therapeutic education of the patient is key to optimizing his or her management, especially for those times when he or she is autonomous (example: taking treatment before and after surgery).

The personalization of the care pathway is even more important: adapt your medical protocols to the particular characteristics of the patient by developing customized products based on the specifications and data from your patients’ medical examinations (MRI, CT scan).

With 3D printing, help improve your patients’ care pathways and quality of life.

OUR offER

Simulate your offer HospiFactory

Are you interested in the concept of a 3D platform dedicated to your establishment and would you like to test it first?

Discover our 3D printed products: our range of surgery simulators, our medical devices and our anatomical models.

Frequently asked questions

HospiFactory is a solution that fits every hospital’s budget. Contact us at contact@bone3d.com and we’ll share with you a customized quote, tailored to your facility and equipment needs!

We adapt the size of the platform to your structure and your expectations. Each HospiFactory is unique, composed of various 3D printing technologies that we make available.

We have written a scientific article on this subject. Read it here for more information.

Today we do not have the capacity to recycle our own parts, it is companies specialized in this field that do it.

However, 3D printing allows an optimal use of the material: there is no waste (compared to machining), no loss of stock and the production of your parts is done nearby.