Bone 3D signs agreement with Stratasys to deploy 3D printing across France's hospital network - October 2021

October 13th, 2021

‘Hospifactory’ initiative to meet increasing requirement from healthcare institutions for on-demand, localized production of 3D printed medical equipment and anatomical models

Stratasys Ltd., a leader in polymer 3D printing solutions, today announced that it has signed an agreement with French med-tech start-up Bone 3D, designed to put Stratasys 3D printing technology directly into the hands of France’s front-line medical professionals.

Via Bone 3D’s Hospifactory initiative, which is available today, healthcare institutions now have direct access to an immediate, cost-effective and localized way of 3D printing essential medical equipment, medical devices and patient-specific anatomical models. Healthcare providers can sub-contract 3D printing hardware and services from Bone 3D, granting them the direct means to fulfil their own production needs on-site, as well as receive dedicated ongoing support from Bone 3D technicians. Under the agreement, Bone 3D will invest in and supply Stratasys’ latest FDM® and PolyJet™ 3D printing systems according to the particular requirements of individual hospitals and medical institutions that are part of the Hospifactory network. The company has already invested in more than 30 Stratasys 3D printers to date.

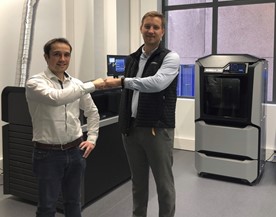

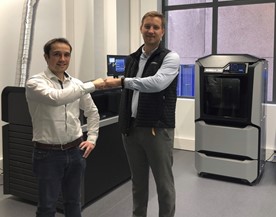

Via Hospifactory, healthcare institutions have direct access to an immediate, cost-effective and localized way of 3D printing medical equipment and anatomical models. Pictured (left) Jérémy Adam, CEO and founder, Bone 3D; and Arnaud Toutain, Healthcare Sales & Development Lead, Stratasys

A shot in the arm for French healthcare

Jérémy Adam, CEO and founder, Bone 3D commented: “Early on in the COVID-19 pandemic, the world witnessed the importance of 3D printing first-hand as it provided a swift and direct means of producing vital PPE to equip frontline healthcare workers, ventilator parts and other critical medical equipment.

“However, beyond that, the versatility of 3D printing has seen huge demand from hospitals and medical institutions for a means to create maintenance parts, rehabilitation parts and medical devices. Our Hospifactory initiative will ensure that some of the market’s most advanced 3D printing technologies are made accessible exactly where and when they are needed by surgeons and clinicians across the French hospital network,” he added.

Bone 3D’s investment in Stratasys 3D printers comprises an array of different systems, including the advanced J750 Digital Anatomy 3D printer, which produces anatomical models that mimic the actual feel, responsiveness, and biomechanics of human anatomy with unprecedented realism; as well as the recently introduced more compact, full-color, multi-material J5 MediJet™ 3D printer. Bone 3D also has acquired several F-Series FDM 3D printers for a range of applications requiring tough, durable parts. This includes everything from medical device development to maintenance parts within hospitals, right through to supporting patient rehabilitation, such as a replacement handle for a wheelchair.

The ability to produce parts locally, on-demand is a gamechanger for hospitals and medical institutions, giving them the power to 3D print the critical parts they need, when they need them

Jérémy Adam continued: “Stratasys’ longstanding expertise in the healthcare industry, and continually-expanding range of 3D printing technologies and medical-grade materials, make it the ideal partner to take Hospifactory to the next level. We now have the full 3D printing package through one point of contact, giving us the production capability and agility to meet the needs of our customers.”

A growing trend for on-demand production

The latest partnership between Stratasys and Bone 3D follows last year’s successful deployment by Bone 3D of 60 Stratasys FDM 3D printers in Europe’s largest hospital system, the AP-HP* in Paris, to support the frontline fight against COVID-19. Bone3D managed the implementation, operation and support of the fleet, which gave the AP-HP its own in-house capability to produce vital PPE, electrical syringe pumps, intubation equipment and respirator valves on-demand, bridging the shortfall in traditionally manufactured equipment.

We continue to see substantial demand for 3D printing within the healthcare sector for a rapidly-broadening set of applications,” said Eric Erickson, Director of Healthcare, EMEA, Stratasys. “The ability to produce parts locally, on-demand is a gamechanger for hospitals and medical institutions, giving them the power to 3D print the critical parts they need, when they need them. The Hospifactory initiative will significantly increase the accessibility of our 3D printing technology to a much wider geographic network of hospitals.”

Established just three years ago, Bone 3D is already a leading 3D printing service provider for the healthcare industry. The team brings together highly experienced engineers and surgeons who boast decades of experience in engineering and medical science. Working closely with Stratasys from the very beginning, the 35-strong company today serves more than 250 customers throughout France, notably the AP-HP, University of Paris and Strasbourg University Hospital.

Find the articles published in the French, British and Spanish press on the collaboration between BONE 3D and Stratasys: L’usine Digitale , Primante 3D, TCT Mag, Medical Plastics news and Interempresas