How can titanium 3D printing revolutionize healthcare?

This summer’s acquisition of a new SLM280 (Selected Laser Melting) titanium machine from SLM solutions is an opportunity for us to revisit the benefits of this advanced technology. Titanium 3D printing is recognized as an additive manufacturing process that promotes excellent mechanical properties for healthcare applications.

However, despite its advantages, the use of titanium 3D printing can present some constraints on its use: the regulatory requirements for titanium medical devices are considerable and the lead times associated with the production/delivery of a titanium printed part can be excessive (up to 5 weeks for often urgent needs).

In this article we share with you the process of this technology, its value, especially in healthcare, and its development potential for the future.

For more information, feel free to check out our other article on the various 3D printing technologies in healthcare.

Titanium 3D printing, why ?

Titanium 3D printing is an additive manufacturing technology widely used in many industrial sectors (aeronautics, space, industry, etc..). It is chosen in particular for its robustness and the complexity of the part design it enables.

In the healthcare field the use of pure titanium (grade 2) is ideal and has already demonstrated excellent results in biocompatibility. This material is strong, light and has interesting mechanical properties that facilitate its bio-integration in the human body, indeed, titanium is osteoconductive.

Currently, few machines on the market work with pure titanium like our SLM280. Yet its advantages are not negligible: greater corrosion resistance and the best possible biocompatibility.

Instead, many use other alloys, often cheaper to produce.

How does a SLM machine work ?

SLM operation: what constraints ?

SLM technology is an additive manufacturing process based on the principle of metal powder fusion.

The atomized powder (extremely fine and fluid) is highly explosive and can ignite on contact with air. To avoid this type of situation, the machine is always under a 98%+ argon environment. To ensure the safety of the production technicians (argon is a noble gas naturally present in the atmosphere, but in large quantities it can asphyxiate), an argon detector is present in the room and starts to beep if the amount of oxygen in the air becomes too low.

How does titanium 3D printing work ?

- The powder in the reservoir flows down into the machine by gravity

- The blade (scraper) in the machine is movable and distributes the powder evenly on the manufacturing tray. It is possible to choose the layer height which is usually 30 microns. The deposit is done in both directions (forward/backward), the scraper comes to scrape the excess powder and drop it into an overflow

- Two laser sources send out two beams that are channeled through two computer-controlled lenses

- The lasers fuse the titanium at its melting temperature selectively according to the “slicing”: the slices of material from the 3D file to be printed

- The local atmosphere is controlled at the platen during manufacturing to control melting and direct waste to filters . This filter is regularly emptied and cleaned

- After each melting step, the scraper re-deposits a layer of powder and the process begins again

- After the final fused layer, the result is a block (called a “cake”) of powder that the technician cleans with a brush, like an archaeologist, to come and dig up and clean the piece . This step requires the use of a specific outfit and is done the gloves in the machine under argon

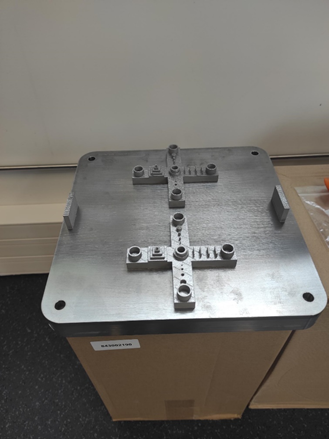

- Then the titanium supports that hold the parts and allow for the dissipation of thermal energy from the lasers must be removed by hand

- Finishing is done with a sandblaster, to strip off the remaining powder. To finish, the medical parts go through a disinfectant washer.

For our machine, the printing trays can hold about fifty parts of the type hip prosthesis, screws, knee etc.

How is titanium powder recycled?

For future printing, the powder is sorted using an ultrasonic sieve (removing oversized grains) and then recycled.

At BONE 3D, we have made the choice to keep this manual recycling process. Indeed, unlike automatic recycling that can be done in routine, we have the ability to control precisely the powder at each printing run . The goal is to analyze and determine from when the powder is too contaminated or too oxidized, and when it is no longer clean for the manufacture of a medical device (MD).

What is the interest of titanium 3D printing in health?

Titanium 3D printing has great adaptability and participates in the production of custom implantable parts in various specialties such as maxillofacial surgery, orthopedic surgery, in osteosynthesis (surgical guides, screws and plates) or for the design of joint prosthesis.

These types of parts are medical devices, and in order to market them it is necessary to certify the titanium manufacturing process.

The SLM280 machine from SLM solutions is a highly reliable device that will enable BONE 3D to ensure the reproducibility of its prints and guarantee its certification.

What are the limits of titanium 3D printing?

One of the main issues that can be encountered with titanium 3D printing today is the time it can take to deliver a part. Currently, the waiting time to get a titanium part is a minimum of 7 days wait (in express), but most of the time this time can reach up to 5 weeks. This period is incompatible with the treatment of patients with certain pathologies.

Let’s take the example of a patient who has aggressive cancer and needs an implant as part of reconstructive surgery: in this case, waiting 5 weeks may doom the patient. Offering him a custom device 100% adapted to his pathology in 48 hours means increasing his chances of survival and quality of life.

What can we expect from titanium 3D printing at BONE 3D?

With the acquisition of this new titanium machine, we aspire to address the current issues in titanium printing: we want to produce locally, bring proximity to hospitals, and provide them with titanium devices much faster than usual while improving the performance of the parts produced.

With our printers located in the center of Paris, we aim to become the leader in implantable medical device 3D printing in the region. We aim to work with all Parisian hospitals initially, then expand to France in a second phase.

Also, with our HospiFactory service, hospital staff can take advantage of a fleet of printers directly at their facility, so they can better understand the challenges of 3D printing and submit their ideas.

Thus, BONE 3D offers proximity, time-saving for healthcare teams and opens its doors to innovative ideas from healthcare staff.

Want to keep up with the latest news from BONE 3D? Follow us on social media LinkedIn, Facebook, Instagram and on Youtube!

The BONE 3D team