Medical 3D printing: 3 examples of innovative health projects!

For the past several years, 3D printing has been gaining interest in both the industrial and medical fields. It is no longer reserved solely for prototyping or for certain specific sectors of activity. Additive manufacturing has now become a leading method of manufacturing, with major advantages such as speed, proximity and customisable production, enabling simpler and wider access to innovation.

The use of 3D printing is becoming more widespread and it’s only the beginning. So how can it be fully integrated into the medical sector and for what applications?

3D printing can be integrated into a personalised care pathway for the patient, can encourage innovation on the part of the caregiver, and can be part of a project development process for a healthcare establishment.

In this article, we propose to :

- Review the concept of 3D printing

- Discover the different uses of medical 3D printing, in a non-exhaustive way

- Understand the points of attention for the implementation of this type of approach

What is 3D printing ?

3D printing is a technology that has been around since the 1980s and is becoming more and more popular and utilized

When we talk about 3D printing we also talk about additive manufacturing. This means that parts are manufactured by adding successive layers of material under the control of a computer.

Unlike traditional manufacturing, this process is interesting because it not only eliminates the need for a mould or specific tooling (if not a 3D printer) but also allows for greater flexibility and speed in the production of customised parts, less waste and hence reduced cost. Above all, 3D printing offers an almost infinite range of possibilities!

And this is undoubtedly why the number of patents filed each year on this technology is increasing rapidly (27% each year). It has also been selected as one of the 10 most important categories in terms of growth over the last 5 years by the IFI Claims Patent Services organisation.

These great advantages and its flexability highlight why additive manufacturing is particularly suited to the needs of the health sector: adaptability to specific patient needs, rapid and local manufacturing, etc.

Surgeons and doctors have understood this because for several years they have been integrating it into their practice and all specialities are concerned.

So, specifically, what are the possible applications in the medical field?

We are obviously thinking of 3D printed and orthoses, for example. But other uses exist and we are now offering you a brief overview of 3 types of applications. These are just a few examples to inspire you, and there are dozens of others.

#1 – Simulators to help improve training of carers

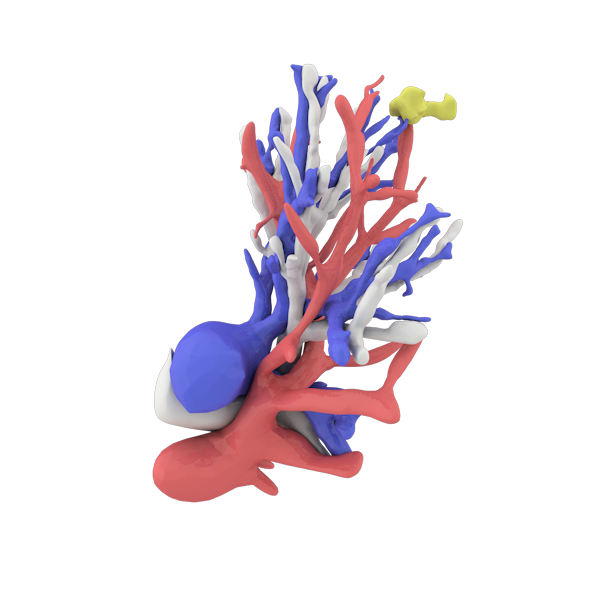

One of the first applications we discuss are surgical simulators. 3D printed, they serve as a training aid for surgeons and surgical interns. Thanks to advanced technologies, the expertise of engineers and the advice of expert surgeons, it is now possible to reproduce different parts of the human body on which carers can train to perform various surgical procedures. Multi-material 3D printing allows soft and hard tissues to be reproduced in a single print, achieving an anatomical accuracy that is difficult to achieve with assembly manufacturing processes. The simulators therefore offer a unique anatomical realism.

This is a major positive contribution to the training of the various practitioners, enabling them to develop their expertise. They can all be trained simultaneously while experiencing the same sensations as those they will encounter during their first operations. This is a unique advantage of medical 3D printing, particularly in the face of other technological innovations such as augmented reality which, although it allows for greater precision, does not offer the touch or resistance of a real operation.

The design and 3D printing of surgical simulators make it possible to reproduce pathologies while avoiding the use of animals or cadavers. Indeed, these solutions can be expensive and require special logistics: they must be available and training must be carried out in dedicated locations. Furthermore, with surgical simulators, ethical issues when using cadavers are no longer an issue. Last but not least, it is possible to reproduce certain pathologies via 3D printing, pathologies that are not necessarily found on cadavers used for training. The 3D printing simulation models make it possible to free practitioner from these heavy constraints: a table and a simulator is all thats needed.

3D printing is also an excellent way to reproduce the anatomy of a specific patient in order to improve preparation for complex surgery!

Simulators can be used for all medical specialties: oral surgery, ear surgery, neurosurgery.

There are various examples: there are oral surgery simulators for maxillofacial surgeons to enable them to reproduce implant placements with all the components of the jaw. There are also simulators for podiatrists.

Finally, a recent phenomenon, for PCR tests, there are anatomical models that allow first aiders, nurses, medical students, pharmacists or even laboratory technicians to practice rhino-pharyngeal sampling.

#2 – Medical devices to provide specific patient care

While there are obviously regulatory constraints to be respected for the creation and use of this type of product, it is entirely possible to design and produce them on 3D printers.

This is part of a long-term approach to innovation, product development and sometimes even patent registration.

This is not the most common use, but it is likely to become more and more widespread and to make “customisable” more accessible to everyone at very reasonable prices.

It can be a first choice solution within the framework of the patient’s care pathway, which we want to be increasingly personalised and adapted. Thanks to additive manufacturing, it is possible to create a unique part for a single dedicated patient.

On the caregivers’ side, it is obviously also an interesting tool for research and innovation with the possibility of co-designing projects with specialised design offices.

While several projects exist or are in the process of being validated, one example of a medical device manufactured via 3D printing is a silicone nostril conformer model used to follow rhinoplasty and cleft lip and palate surgery in order to allow better control of the scar area. The advantage of additive manufacturing in this case is the quasi-customisation of the MD (medical device) which adapts to the size of the patient.

#3 – Small medical equipment for everyday use and hospital staff

Beyond surgical simulators or medical devices, it is also possible to consider any other type of medical equipment. And thus meet the daily and immediate needs of the nursing staff. This often involves small-scale equipment produced in small quantities (sometimes even individually) which would not necessarily be easily accessible or at a lower cost, such as protective visors for example.

The covid crisis has revealed a strong interest in this type of solution with the emergency 3D printing of protective equipment, for example, which does not need to go through the red tape of MD.

Also within health establishments, medical 3D printing makes it possible to meet the demands of everyday life in general services: repairing a broken door handle or manufacturing small parts to improve the reparability of hospital equipment. Temporary DIY solutions by biomedical engineers are avoided and hospital managers and purchasing departments save money.

A 3D printing platform in a healthcare facility, good or bad idea?

A printing platform composed of 3D printers installed in a hospital

These 3 applications show part of the scope of what can be done with additive manufacturing in the health sector. So obviously, the desire to invest in a 3D printer today and to equip an establishment or practice may be great.

However, there is one essential element that is important to bear in mind: not everyone is a 3D printer user. Specific engineering skills are required to take full advantage of these tools for medical use.

The good news is that for several years now, engineers have been training on these tools. By combining the high technology of printers with the cutting edge expertise of engineering teams, it is quite possible to create quality and useful medical equipment, which will not only offer patients an improved care pathway, but also provide doctors with cutting edge innovations and hospital staff with immediate responses to small everyday needs.

Resorting to this type of innovation is an essential step for a health establishment that wishes to develop its research elements but also to reduce its costs and enhance its projects.

So a piece of advice: 3D printing enables design freedom , the most efficient method is to be accompanied by the team of bio medical engineering experts at Bone 3D to insure the project will succeed

—

And do not hesitate to exchange with your peers, to share your ideas, because it is only with communication between the nursing staff that these initiatives will be able to grow and impose themselves as a complementary and solution.

If you want to know more about Bone 3D’s activities, don’t hesitate to add us on Linkedin!