Why do a thesis in medical 3D printing: a researcher's testimony

Hello Maya! Could you introduce yourself and explain your background?

Hello! My name is Maya Geoffroy, I am doctoral student in the 1st year of a CIFRE thesis between BONE 3D, the Institute of Human Biomechanics Georges Charpak and the Necker – Enfants Malades Hospital.

I did two years of PACES (medicine), then a post baccalaureate general engineering school called EPF. I then did a specialization in health engineering at Sceaux. Finally I did my last year of engineering in a research master at the Institute of Human Biomechanics Georges Charpak.

Since my graduation, I worked for about a year at BONE 3D for different projects such as the development of a prototype of a foot-bot orthosis or the participation in the 3D printing platform of the AP-HP based at the Cochin Hospital. Since last July, I started my thesis work, which focuses on the biomechanical study of craniostenosis.

How did you come to this choice of thesis in 3D printing?

I had already worked at EPF on 3D printing, we had a Techlab that directly interested me a lot, especially the medical projects as I had done PACES before. In addition, they were research projects, which made me want to continue my studies.

Then there was the research master’s degree that helped me develop my methodology. And I was very lucky to find this thesis because it was the first subject I was offered and I threw myself into it directly ! I didn’t have any particular difficulty in finding my thesis after all.

Why this choice to do a thesis with an industrialist ?

The thesis CIFRE (industrial conventions of training by research) was proposed directly with BONE 3D, which already had quite strong partnerships with the institute and the hospital. I was also interested in developing a product at the end of my thesis, something material, and not just computer models. You need both the knowledge associated with 3D modeling and the ability to produce it in fine. I need to have something concrete, that was one of the key criteria for choosing my thesis.

What are your main issues and challenges ?

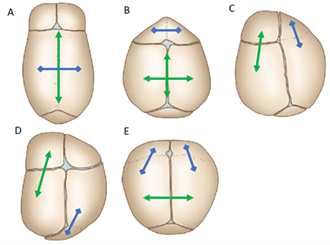

To remind you of the background, at birth, all the sutures in the skull are “open” but for some babies this is not the case. This is called a craniostenosis. It is a rare condition that affects 1 in 2500 births. It does not seem like much, but at Necker Hospital it is one to three surgeries per week.

In these babies, there is one or more sutures that close before birth and so the brain will continue to grow but not in all directions. It will push the skull to grow in abnormal directions. These babies may have a skull with a particular shape (a little triangular or with a bump on one side), which can cause mental retardation and cosmetic problems. The treatment consists of a rather heavy and risky surgery, performed around 9 months from birth.

Today, this surgery is done at the surgeon’s experience with very good postoperative results. However, there are several surgical techniques performed at a different age depending on the surgical centers. The challenge of my thesis is to comparing the techniques and potentially improving the surgical outcome.

What are the things that challenge you on a daily basis ?

It’s precisely working on a subject that is concrete, that affects many patients who are treated at Necker, and having a tool at the end that will be useful for surgeons several times a week. It is all the more rewarding that the project is being done with surgeons who are experts in the field. They make themselves readily available to answer clinical questions.

Also, you stay in training during the thesis, so you learn about new methods, company products, and how to present your project well – depending on the audience. It’s really rewarding.

In your opinion, what is the interest of 3D printing for your project, and in healthcare in general?

For my project, the interest of 3D printing is to personalize a product that must be adapted to the geometry of each patient, while being accurate and produced relatively quickly . A common and automatic process will be developed where the only variable will be the geometry of the patient. 3D printing has all its interest because it will easily fit into the process and allow to print a specific device according to the anatomy of each patient.

And overall for healthcare, I would say that it’s the materials that are used in 3D printing that have a high added value. Many materials that are already used in more conventional production techniques are being developed or already marketed: we can use resin as much as metal. So today we can produce quickly and to measure thanks to 3D printing.

How do you collaborate with all of your thesis stakeholders ?

The follow-up is very important. I travel a lot between Necker hospital, the institute and Bone 3D, and we try to make a maximum of follow-up meetings with all my thesis supervisors to collect the industrial, clinical and research opinions as well. My 3 supervisors are :

– Sébastien Laporte, Director of the Georges Charpak Institute of Human Biomechanics

– Pierre-Marc François, CTO of Bone 3D

– Roman Hossein Khonsari, surgeon specializing in Pediatric Maxillofacial Surgery at Necker Hospital

At the hospital it also allows me to meet surgeons, to go and see operations and therefore to better understand their issues.

Finally, what would be your recommendations for future candidates who would like to apply for a thesis in 3D printing?

For a thesis in general, you have to be careful that the subject appeals to you in order to commit to three years. It is also important to know a minimum of one’s supervisors to be sure that the collaborations go well.

Furthermore, as far as 3D printing is concerned, I think that one should be interested in this field without necessarily knowing perfectly all the techniques that are used. For example, I knew very well the techniques of hot wire deposition, and I was not particularly an expert on the other techniques. Here it was all the interest to make a thesis with an industrialist because I could train easily. And now I know that for the future I will be able to have more choices in what I will use in terms of technologies.

Also, doing a thesis in 3D printing gives access to a diverse range of topics this can range from its application to develop a final product, to more fundamental research to improve printing technologies and materials.

Anyway, I’m all in on my thesis, I’m still enjoying it and everything is going great ! I recommend !

Thanks Maya for these answers, it makes you want to start a thesis in 3D printing!

To conclude on this article, we wanted to share with you some key figures on CIFRE theses from their site.

FUTURE DOCTORS IN 3D PRINTING : GO TAKE A LOOK!”

Did this article give you any ideas?

Contact us on our website or let’s stay connected on social networks!

Also, don’t wait any longer and come discover our latest news on our channel Youtube.